Geotech risk management: why it pays to build it into your mine design from the outset

Adam Kerr, Senior Engineering Geologist, Cartledge Mining and Geotechnics

Sound geotechnical analysis can have myriad positive effects on mine design, planning and productivity and the earlier geotechnical teams are introduced to the design process, the greater the benefit.

Design optimisation is often at the forefront of the minds of mine planning teams. Questions like ‘Where can we maximise our recovery and minimise our costs?’ and ‘How can we build safety into our everyday operations?’ plague discussions and decisions in the early phases of mine design.

By involving geotechnical engineers at this crucial juncture and giving them a greater influence on mine design can allow for improved designs, optimised resource recovery, optimal safety outcomes and a better financial return.

Using improved model accuracy, according to variations of ground conditions, geotechnical engineers may be able to adjust the mine design by modifying slope designs in certain areas, which can significantly offset the costs of any problem areas.

Moreover, geotechnical analysis can be linked to the project development cycle, with the most effective stages of hazard management occurring in the design phase. Once the design is complete, risk minimisation is less effective and difficult to design geotechnical hazards out.

Failing to integrate geotechnical analysis into mine design can lead to severe safety and financial consequences and yet some miners continue to undervalue this area of the sector.

Most miners agree geotechnical analysis is a crucial element of the mine design process. However, some fail to continue to properly incorporate this element into mine designs putting personnel at risk and potentially exposing mining projects to millions of dollars in lost production time and revenue.

Good geotechnical analysis will identify potential pitfalls and hazards, well before actual mining occurs.

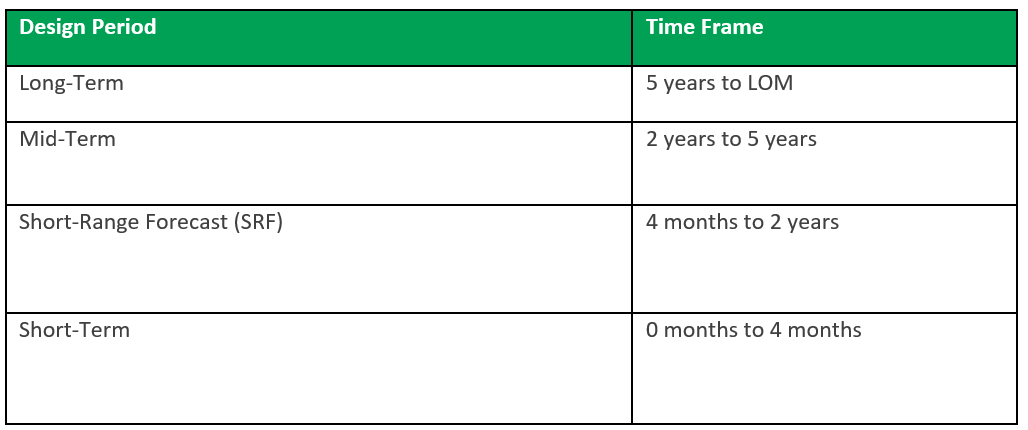

In best practice, mine sites generally follow the below design process with varying time frames between individual companies and sites.

Detailed geotechnical design will be undertaken in the 4 months to 2 years period with increased resolution of, and confidence in the design across the two design periods (SRF and Short-Term). The purpose of each design phase is as follows:

Long-Term – Geotechnical analysis can identify critical, high-risk hazards that require long-term options, including design change and other factors to mitigate against. Define programs to improve understanding of these hazards (e.g., additional studies for alternative designs, exploration to improve confidence in critical inputs, fault location, geology, rock mass conditions, etc.), and conceptual mitigation options. At this point, geotechnical analysis will identify and inform high-level risks.

Mid-Term– Geotechnical analysis will define geotechnical hazards, implement mitigation options, conduct additional work to define confidence in the location of known hazards, and develop options where operational controls can be used to manage lower-risk hazards.

Short-Range Forecast – Geotechnical analysis will identify low and moderate-level geotechnical hazards and develop programs to improve confidence in critical inputs. Improved accuracy from operational data (e.g. mapping) will assist in finalising short-term designs.

Short-Term – Geotechnical analysis will validate the SRF design, geology and geotechnical models against observed pit conditions to produce Operations Hazard Management Plans.

Review and Reconciliation – Geotechnical analysis will review mining performance against expected ground conditions and provide feedback to Technical Services team and input to SRF design process.

Figure 1: Hierarchy of controls

It is recommended that the Mid-Term processes are undertaken annually in line with model / plan updates while SRF designs are reviewed and updated quarterly. Short-term designs are undertaken on an ‘as required by operations’ basis.

Geotechnical risk is dynamically assessed at each stage of the design period. The accuracy of the data that is used, and the certainty of which our design recommendations are given, theoretically increases as we move towards short-term operation.

The hierarchy of risk controls is a commonly understood tool within engineering to determine the most effective options at risk reduction. The hierarchy lists a range of controls from most effective to least effective. The hierarchy map is to the right.

Table 1: An example of geotechnical controls to mitigate hazards for each stage of the control hierarchy

It is worth noting that the selection of hierarchy controls can be limited based on which stage of mine design the project is at. As you progress through the design phase, you can see that the efficacy of Control’s available decreases. While higher order Controls can be adopted at later phases of the design process, however, the impact and cost is significantly higher than if they are implemented at an appropriate stage within the process.

You can see that once projects approach the SRF and Short-Term periods, options available to the geotechnical engineer are limited to using lower order controls. Administrative and PPE Controls rely on human response to a situation and are a reactive control rather than a proactive one (i.e. elimination, substitution). These controls are designed to protect equipment and operators, but can still result in significant economic impact to a project.

While using specialist geotechnical engineers to conduct thoughtful analysis from a mine design’s inception can be a significant upfront cost, it pays dividends in terms of optimal resource recovery, improved safety, and more favourable financial outcomes, throughout the entire life of the project.

Good advice is never cheap but ignoring it can be costly.